|

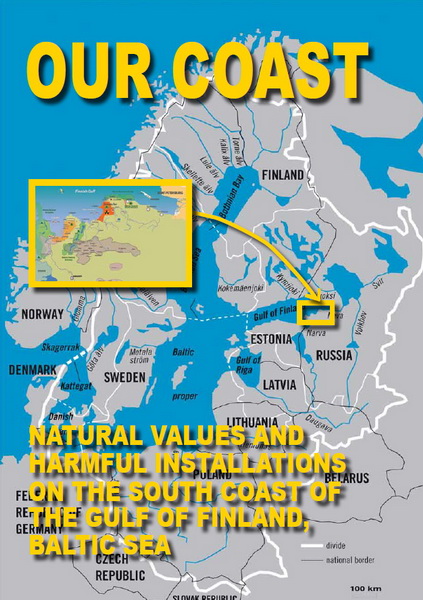

The South Coast of the Gulf of Finland |

|---|---|

| Natural Values and Harmful Installations |

|

Concept of a decommission plan for old nuclear power reactors |

|---|---|

| Guiding Principles from Environmental NGOs |

Papuans on the Nuclear Field

What is Going on at the Construction of the Leningrad Nuclear Power Plant-2?

The “Rosatom” state corporation has blundered once again:

Nadezhda Popova, the International Bureau of Journalistic Investigations.

Nadezhda Popova, the International Bureau of Journalistic Investigations.

Aleksey Schmidt, Editor of the Investigation Sector , “Objective”

On March 3, this year, a participant of the Leningrad AES-2 construction (this nuclear plant has to succeed the ancient 40 years old Leningrad AES-1) gave an extensive devastating press conference on this nuclear project construction in the Leningrad region. Victor Aleynikov is a professional builder with an extensive work experience at atomic plants construction sites. As he states there are so many infringements, miscalculations, frauds at the project construction that one can hardly enumerate them. It is likely that the «Ostrovets» NPP in Belarus is being constructed in the same incompetent way and the same surprises can be expected at the “Hankikivi” nuclear power plant being built by “Rosatom” in Finland. Ordinary Finns are discussing this construction project in social networks, namely in the Facebook, very violently. What is happening on the nuclear projects of “Rosatom”? Who is building them and how?

Negligence is dangerous not only for Russia

Victor Aleynikov started his press conference with the words: “I am addressing to you, journalists, because the appeals to the immediate superiors of the Leningrad AES-2 construction project, to the government supervisory authorities haven’t achieved the expected results. But the possible global negative consequences of the construction technologies violations at the Leningrad AES-2 may be a danger not only to residents of Sosnovy Bor, but also to St. Petersburg, all the Northwest region of Russia and the Baltic Sea countries. I am going to tell you about the general atmosphere and spirits of the builders at the Leningrad AES-2 project, about the construction technologies violations, falsifications of results of the main circulating pipeline’s (MCP) welding joints heat treatment at the first contour of the rector of VVER-1200 in reactor shop of the first Leningrad AES-2 power unit. I will also tell about the financial frauds».

The “Objective” international magazine’s note:

The most part of Victor Aleynikov’s professional experience is connected with the nuclear branch. Victor Aleynikov is the holder of the «Veteran of Nuclear Power and Industry» medal. Short biography: After graduating from the ship-building technical college in Nikolaev (Ukrainian Soviet Socialist Republic) and receiving the specialty of a ship electrical technician in 1978 he was assigned to work to Sosnovy Bor, Leningrad region, the Research Technological Institute (RTI named after Alexandrov). There Victor took part in submarines’ nuclear reactors tests as a ship nuclear reactor electrical power system operator. In 1991 he took up a job of an electrician-operator of automatic and measuring equipment at the Leningrad nuclear power plant. Since November, 2009 he has worked for the “Tunnel Group-3” CJSC at the Leningrad AES-2 construction project.

How they swindle with concrete

I saw with my own eyes the violations of the construction technology at the Leningrad AES-2 project, particularly in the concrete works, — continues his story Victor Aleynikov. — According to the instruction, filling of concrete should be carried out at a lowest temperature +10о C. But this temperature condition wasn’t observed when carrying out concreting. Filling of concrete in 10 UKT (fresh nuclear fuel storage building) and 10 UKA (safety building) buildings was carried out at negative atmospheric air temperatures. For the diesel fuel economy the management instructed not to use all the “Galaksi” heat guns intended for heating when concreting in the curing tent. Thus the temperature condition of concreting wasn’t observed.

How they swindle at welding

From February, 2010 to February 1, 2016, I worked as a service technician of the welding and gas-plasma cutting equipment of MSU-90. My responsibility was maintenance and repair of the welding and plazma cutting equipment including those on the Leningrad AES-2 construction site. MSU-90 is a part of the TITAN-2 trust where the chairman of the board of directors is G. Naginsky, the ex Federation Council member representing Leningrad region, ex Deputy Minister of Defence of the Russian Federation. In March, 2013, the chief welder of MSU-90 Shubinsky A.V. assigned me to the training course on the specialty «operator of mobile thermal units». I wondered why I, a service technician, needed it. And the deputy chief engineer Nikolay Gusev answered that the LAES-2 reactors pipeline’s responsible welded connections and the other responsible welded connections at the new plant would be heat treated and they needed qualified heat-treaters for this purpose.

А group for training operators-heat-treaters was formed. It included:

From the chief welder group:

Aleinikov V.

Prosvirin A.

Kornilov E.

Installers from division №1 of MSU-90:

Abdullayev M.

Anohin V.

Lukin Mikhail

Makarov Pavel

Salnikov Vasily

Tudvasev Alexander

Two teachers from the private “Elektromontazh» Northwest Training Center” gave the group a three weeks theoretical course on heat treatment. Then we had two trial practical works on heat treatment. And I was given a «Diary of a professional retraining student’s professional practice» supposed to be filled in during the practical training. But we did not have any practical training. In autumn of 2013, I needed my certificate of a service technician for a trip to the Leningrad AES-2. The certificate was in the chief’s office. Seeking for my certificate in the chief’s desk I found the diploma of an «Operator-heat-treater of mobile thermal installations» No. 040-13 written out on my name and «issued» on June 3, 2013. But hadn’t passed any practical training, certification or examination on the operator-heat-treater profession. The other mounters who participated in the course on heat-treating were also not aware of the diplomas, and didn’t have any information on it. It was a surprise for us that we were «diplomaed heat-treaters».

At the beginning of 2014, the new chief welder of MSU-90 Ruslan Sekachev asked for my operator-heat-treater diploma’s photocopy. To my question why he needed it he answered that MSU-90 must have the confirmation of the provided training.

How they swindle at heat treatment

At the end of 2013, the chief welder of MSU-90 R. Sekachev reported that they want to send me out to turbine shop No. 2 for heat treatment of the responsible welded seams of the ring which is the basis of a big important tank. I suggested MSU-90 to conclude an additional labor contract to combine the service technician’s work with the work of an operator-heat-treater. But Sekachev answered that this work should be performed as an unofficial by-work. Then to check the reaction of the chief, I asked for a five thousand rubles payment for the “unofficial by-work” shift. In a week Sekachev answered that the deputy chief engineer Gusev had not agreed with that condition. And I was assigned to heat treatment of welded seams as a service technician. In that capacity I had to control operability of the “Weldotherm” thermoinstallation and eliminate malfunctions. The process of the ring heat treatment was controlled by the workers of MSU-90, Ukrainian installers without any special qualification of a heat-treater (!).

In September, 2014, the works on welding and heat treatment of the welded connections of the Leningrad AES-2 first power unit’s main circulating pipeline (MCP) started.

The reactor’s first contour MCP consists of four independent loops. Each loop consists of a steam generator, the main circulation pump (MCP) and pipes connected by 7 welding joints. Each loop has two welded MCP joints to the reactor, two welded joints to the steam generator, two — to MCN and one welding joint of the pipeline between the MCN and the steam generator. Thus, there are 28 welding joints on the first VVER-1200 reactor power unit contour’s MCP four loops. From the welders I learnt that each joint is estimated at 8 million rubles, that all this work costs about 224 million rubles.

The heat treatment mode provides «heating under welding». After welding of a joint and the welded connection quality control a «high-temperature tempering» of the welded connection and its «thermorest» is carried out. These works were carried out with two types of thermoinstallations: German «Weldotherm» and Russian “Kuray” high-frequency induction type installations. The “Weldotherm” installations worked faultlessly. And the “Kuray” installations often broke down and constantly needed repair. The personnel’s work shifts lasted for 12 hours. In October, 2014, we had 21 shifts that is 252 hours per month. Such intensive work schedule increases the probability of mistakes. The most important high skill work of heat-treaters was performed by the workers with phoney diplomas and their work was paid less than requires the Labour Code of the Russian Federation.

How they swindle with the thermoinstallations

At the end of 2014, coming to my work place after a day off, — Victor Aleynikov continues the narration, — checking the equipment in “Kuray” thermoinstallation control cabinet I noticed foreign elements on the terminal block connected with wires to the thermocouples controlling the temperature of the heat treatment of the MCP welding joint to the reactor. These, irregular connected elements were four variable resistances that allow to change the thermal e.m.f. of the thermocouples during heat treatment of the welded seams. This ruse allowed the heat treatment operator to change randomly the course of the welded seam heat treatment chart by regulating the variable resistance. This makes it possible to show any technology required temperature value in the welded seam heat treatment protocol though the real temperature value can be absolutely different. This violation was revealed at the completion of the «high-temperature tempering» (many hours long heat treatment mode) intended for removal of residual voltage of the MCP third loop welding joints connection with the reactor vessel. High-quality heat treatment of such connection is very important because removal of internal voltage from the welded seam directly influences the soundness, durability and safety of functioning both the reactor and the whole nuclear power plant. Violation of the heat treatment technology is a potential threat of the connection destruction that can cause radioactive pollution of the Northwest region of Russia and the Baltic Sea area.

Having disconnected the irregular variable resistances, I threw them away. But when I came to work on January 5, 2015, while checking the «Kuray» equipment after the welding joint «high-temperature tempering» completion, I found out again that the variable resistance was connected parallel to the thermocouple compensation wire of control point No 2. Having photographed with my mobile this connection and the chart of the «high-temperature tempering» on the recorder, I reported the shift senior engineer on this violation. That day was remarkable also by a Hungarian delegation visiting the reactor shop. Their photographer fixed all the details in the reactor shop, and the deputy director of the Leningrad NPP was proudly telling about reliability of the new nuclear power plant under construction.

How they swindle with specialists

Upon completion of the welding joints heat treatment works I returned to my main workplace to the «Bentam» building belonging to MSU-90 of the “TITAN-2” holding. But I had regularly to go to LAES-2 to repair the welding equipment or the “Weldotherm” thermo installations that had been transported to the turbine shop No1 of the LAES-2 first power unit. There they were used for heat treatment of the pipelines welded joints. On my next arrival to turbine shop No1at LAES-2 (on February 21, 2015) to repair the “Weldotherm” installation I was surprised to see an unknown man doing the heat treatment . It turned out that the experienced heat-treaters dissatisfied with their salaries had left the site. And now the work was carried out by unqualified Ukrainian assemblers from MSU-90!

On February 25, 2015, in one of the «Bentama» welding cabins where the welders looking for employment were welding samples for appraisal, I saw the operating installation consisting of the welding transformer supplying power to mats which heated a big piece of metal rolled up in thermal insulation. The heat treatment program was set up on the «Teromdat-14E» programmator operating the contactor supplying power to the heating mats. And the recorder drew the chart of heat treatment. On my question: «What is it?»,- the service technician who was carrying out this operation explained that some heat treatment chart at the Leningrad AES-2 was rejected and it is «drawn» anew, it was elementary forgery. The fear to lose job forces workers to commit obvious construction technology violations and forgery. Correction of mistakes requires time, and it is costly! It is easier to forge the required heat treatment result and keep silent about the problems. Those who make bold not to agree and contradict the administration, do not linger on there. They are given the underpaid work and as a result they leave.

How they swindle with salaries

What else surprised me greatly? – Victor Aleynikov continues. — It surprised me that during the period of 2013-2015 years very many welders from all regions of Russia were employed for work at LAES-2. After appraisal, they went to the welding site. Some welders were recruited through intermediary companies. And the welders got their salaries from those intermediary companies really working at the LAES-2 construction under the MSU-90 direction. To my estimate , 70% of welders didn’t linger more than 3 months on the welding site of LAES-2. What was the reason?

Here is a concrete example. A welder from Kaliningrad who worked at cooling condensers welding in turbine shop No 2 told me that he was going to leave:”I am fed up with the conditions at this office. I have come to work and earn money and the foreman offered to record Saturday and Sunday as my working days and the salary for the weekend I am supposed to give him. But I have come here to earn my living and I am ready to work on Saturdays and Sundays. Then the foreman put me on the lowest paid work». Another example of a «shy» foreman who borrows from a welder 10 thousand rubles for a week and in a week he declares: «Sorry, I have no money, but I will record Saturday and Sunday as your working days and you can have a rest and you will receive the money I have owed with your salary».

On the temporary toilet booths’ walls of the on the Leningrad AES-2 construction site one can learn a lot of what the constructors working at the «building of the century LAES-2» think and of their morale that certainly affects the construction and adjustment works quality.

How masterly they steal whatever they find

Theft on LAES-2 is a common thing. Before when I worked at “Tunnel Squad № 3” (TO-3) CJSC of «Metrostroy» that participated in the nuclear reactor foundation construction I witnessed how the deputy supervising foreman instructed the workers to steal a water tank from the adjacent organization. Then the workers of TO-3 stole battens from neighbors to construct a heated shelter because their manager offered them to solve the problem by themselves. Later all the electric tools were stolen from that shelter.

In autumn of 2013 somebody cut a six forty-meter loops off the semiautomatic welding devices with a 95 square millimeters section power copper cable in turbine shop No 2. Later more than ten angle grinders and ten small-sized welding inverters were stolen from the same turbine shop No 2. It is known that fish goes rotten by the head. Subordinate employees emulate the managers both in upward distortions and theft.

What are they constructing in Finland?

A nuclear physicist, the Chairman of the «The Green World» Board (the city of nuclear scientists Sosnovy Bor) Oleg Bodrov says:

On February 3, «The Green World» received V. Aleynikov’s open letter which shows his vision of the serious problems related to violation of technologies and mounting at the Leningrad AES-2 construction.

This information has been already sent to the Committee on Natural Resources of the State Duma of the Russian Federation, to the Legislative Assembly of the Leningrad region and Legislative Assembly of St. Petersburg, to the standing commissions on ecology. The letter appeals for the comprehensive check of the stated facts and taking measures for elimination of serious violations which can affect the safety of the Leningrad AES-2 under construction.

It should be noted that Finns show genuine interest in the problem construction of the Leningrad AES-2.

— The Finns’ interest is connected not only with the fact that the Hankikivi nuclear power plant project uses the same VVER-1200 reactor type as the Leningrad NPP, but also the fact that “Rosatom” appointed the TITAN-2 concern, which is working at the Leningrad AES-2 construction, as the main contractor of the building site in Finland, — Oleg Bodrov said.

Thus, the system problems of TITAN-2 like low level technological culture and technical conscience can also affect the Finland NPP safety.

Why has Hungary refused the Russian nuclear credits?

Apparently, the glory of “Rosatom” is worldwide … Let’s remind you of the fact: in November of 2015, the European Commission commenced an investigation of Hungary’s plans for financing of two new nuclear «Paks»NPP reactors construction. “Rosatom” was stated to undertake the construction of these power units. But still the construction of the Paks nuclear power plant has been suspended … A few days ago it was informed that the authorities of Hungary would not attract the Russian 10 billion euro loan for construction of the two new power units until the European commission gives the positive resolution. This was confirmed by the Head of the Hungary Prime Minister’s administration Janos Lazar to the ecologist, the member of the European Parliament Benedekt Yavor. In January, 2016, the parliamentarian sent a letter to Hungary to learn the reason of cancelling several state procurements on the «Paks» NPP expansion. The member of the European Parliament also reminded in his message that the European Union did not insist on Hungary’s procurements suspension until the end of the investigation. In response to this the authorities of Hungary reported that the European Union did not really request to suspend the government procurements for the NPP project, but the country itself had taken this decision. The government won’t take the 10 billion loan from Russia for the two blocks construction until the investigation ends. It should be reminded that earlier Atilla Asodi, the authorized member of the government of Hungary on the «Paks» NPP expansion issues declared that the EC had three questions on the project implementation.

The first: is the construction of the two new NPP power units legal?. The second: are there government subsidies provided for the blocks construction? The third: why was the “Rosatom” corporation chosen as the general contractor? Let’s recall that Russia and Hungary came to agreement on construction of 1000 and 1200 MW power units in 2014. The parties signed a contract on the station maintenance service and fuel supply. But in February, 2015, the European Commission representatives stated their official position regarding the «Paks» NPP construction having expressed their concern that 80% of the construction cost are undertaken FOR SOME REASON by Russia (being in a very deep crisis).

But recently official Budapest expressed interest in construction of a gas interconnector between Hungary and Romania for having access to the natural gas deposits in the Black Sea. Thus, it is quite likely that new power units for the «Paks» NPP will not be built by the “Rosatom” State Corporation. Anyway, both Hungarians and Finns should learn more of how the Leningrad nuclear power plant-2 is being constructed. It looks as if the nuclear plant builders are Papuans! We can remind also of the emergency on the Leningrad AES-2 on July 17, 2011, when a large-tonnage metalwares collapsed. This happened on the first power unit building site. Mass media mentioned casually of the accident and the collapse of the metal constructions they named as «deformation» of fittings. But the “Novaya Gazeta” published а photo of the collapsed metal net showing the calamitous consequences. The publishers found out the details which make the safety and reliability of the future nuclear object doubtful. Neither in the USSR nor in Russia they have ever faced such blunders at construction of nuclear blocks’ walls. Construction of nuclear objects was monitored by a number of controlling organizations in the USSR. Nonprofessionalism was impossible. Today the facts of bungling, incompetence, defects and direct violations are pretty common, and the construction works at such important object are made by non-residents, non-professional foreign “guest workers” being treated as slaves.

— Any nuclear object and its security system are confidential from its design stage – they are the country secret, — the doctor of engineering, professor Igor Ostretsov says. Admission of Ukrainian workers to such object is simply unacceptable. So this enables to draw a conclusion that they are illegally engaged in construction of LAES-2. And for «closedness of the cycle» any external control over the “Rosatom’s” object is practically impossible, any structures, even the FSB, aren’t authorized to check the qualification and other qualities of the workers or the building materials, technical documentation.

By the way, the nuclear scientists a month before the emergency complained of incompetence of the designers and builders … But who has heard them?

The FSB can interfere only in absolutely extremely emergency cases like terrorism. But if, for example, the wall of the built and launched power unit crashes down it will be the prosecutor’s office to deal with it. So they were the experts of the same “Rosatom” who were looking into the reasons of the fittings collapse. It was a mere chance that there were no victims because it was lunch time and the workers left the site just before the accident. They were the same lucky in January, 2011, when the wind gust destroyed the 14-meter reinforcing wall. Still earlier, in December, 2010, construction of the Leningrad AES-2 was completely suspended for numerous violations of the fire safety standards and the sanitary and epidemiologic norms. Consequences of that emergency are far not so harmless as it may seem. Some experts evaluate them as catastrophic. 1200 tons of the reinforcing steel of the destroyed wall were to be dismantled. Then they had to survey the four-meter concrete layer of the external protective cover of the block. So far all this occurs on the idle nuclear power plant. But if the defects show themselves on the operating nuclear object, it can cause catastrophic consequences …

So what else can «Papuans» of “ Rosatom” construct?

The «Objective» international magazine’s editorial office will inform the Investigative Committee of Russia, the FSB and the Security Council of Russia of this publication.

Nadezhda Popova, the International Bureau of Journalistic Investigations.

Aleksey Schmidt, Editor of the Investigation Sector , “Objective”